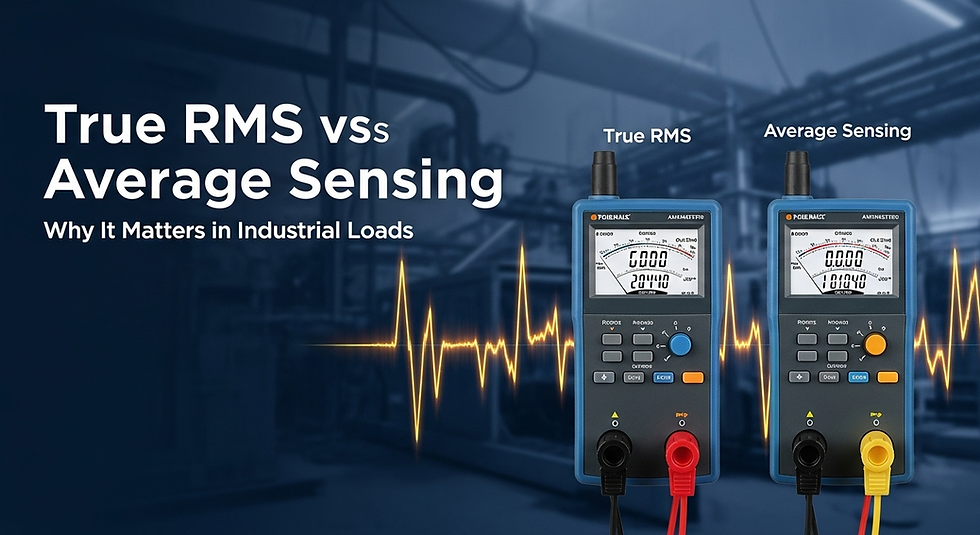

True RMS vs Average Sensing in Digital Ammeters: Why It Matters in Industrial Loads

- teddymccb

- Oct 7

- 6 min read

When engineers and procurement specialists select digital ammeters for industrial systems, the decision often seems straightforward: choose a reliable model, match the current range, and ensure compatibility with the system. However, one subtle yet crucial specification can dramatically influence accuracy and performance, whether the ammeter uses True RMS or Average Sensing technology.

In industrial environments filled with non-linear loads, variable frequency drives, and harmonic distortion, understanding the difference between these two sensing methods can prevent costly measurement errors, equipment failures, and poor power quality management. Let’s explore what each technology means, how they differ, and when to use one over the other.

Understanding the Basics of RMS and Average Sensing

Electrical current can be measured in different ways depending on how the waveform behaves. In an ideal world, every electrical system would operate on a perfect sinusoidal waveform. In such cases, average sensing meters can estimate current or voltage accurately enough. But industrial environments rarely offer “ideal” conditions.

RMS Defined

RMS stands for Root Mean Square. It is a mathematical expression that defines the equivalent steady DC value that would deliver the same amount of heat or power as an AC waveform.

In other words, the RMS value reflects the true energy content of a current or voltage waveform, regardless of how distorted or complex that waveform may be.

Average Sensing Defined

An Average Sensing ammeter measures the average value of the rectified waveform and then applies a calibration factor (typically 1.11) to estimate the RMS value—assuming the waveform is perfectly sinusoidal.

This assumption works fine for clean power systems. However, once you introduce harmonics, switching power supplies, or electronic drives, the waveform shape deviates from a pure sine wave, making average sensing unreliable.

Why Industrial Loads Complicate Measurement

Modern industrial systems rarely run on simple, linear loads anymore. They include a wide variety of electrical equipment that distorts current and voltage waveforms.

Here are some common examples of non-linear industrial loads:

Variable frequency drives (VFDs) used in pumps, fans, and compressors

Inverters and rectifiers used in renewable energy or UPS systems

LED lighting systems with switching drivers

Welders and induction furnaces

Computer power supplies and automation controllers

Each of these devices alters the current waveform, creating spikes, harmonics, or chopped signals. The result is a distorted waveform that no longer resembles the neat sine wave for which average sensing was designed.

If a measurement device cannot correctly interpret the real heating effect of this distorted current, the readings will be inaccurate, sometimes by 20% or more.

The True RMS Advantage

1. Accurate Readings in Non-Linear Conditions

True RMS meters measure the actual power-carrying capability of the current, regardless of waveform shape. They compute the square root of the mean of the squares of instantaneous current samples, which gives a precise result even for distorted waveforms.

This makes True RMS digital ammeters the preferred choice for industrial plants with drives, converters, and automation systems.

2. Better Protection for Equipment

Accurate current measurement ensures that protective devices, such as relays, breakers, and overloads, are sized correctly. When meters underreport actual current (as average-sensing meters often do in non-linear systems), it can lead to overheating, insulation failure, or premature aging of motors and transformers.

3. Improved Energy Monitoring and Power Quality

True RMS measurement helps facility managers monitor energy consumption accurately. This precision supports predictive maintenance, energy audits, and compliance with ISO or energy management standards.

4. Consistency Across Power Conditions

Industrial facilities often experience unbalanced loads, voltage fluctuations, and transient events. A True RMS meter maintains reliable accuracy across all these conditions, providing stable readings that operators can trust.

Average Sensing: When It Still Works

Although True RMS is generally the superior technology for complex industrial systems, average sensing meters still have their place.

Clean Power Systems: In applications where the waveform is nearly sinusoidal, such as basic heating systems, resistive lighting, or small-scale motors, an average sensing ammeter performs adequately.

Cost-Sensitive Projects: True RMS technology involves more sophisticated electronics and processing. If your budget is tight and your load characteristics are simple, an average sensing model may offer enough precision at a lower cost.

Training and Low-Risk Use Cases: For educational or low-voltage demonstration setups, average sensing offers a simpler and economical choice for basic current monitoring.

However, the moment you connect non-linear loads, use inverters, or encounter harmonics, the extra investment in True RMS technology quickly pays off through better accuracy and fewer maintenance issues.

Real-World Example: Measuring a Non-Linear Load

Imagine you are measuring the current drawn by a motor running through a variable frequency drive. The drive chops the input waveform to control motor speed, producing a highly distorted current profile.

An average sensing meter will interpret this chopped waveform as if it were still a pure sine wave and apply the same calibration factor. The reading might show 8.5 amps.

A True RMS meter, however, calculates the real heating effect of that waveform, which could be closer to 10 amps. That 1.5-amp difference may seem minor but can mean the difference between running equipment safely or exceeding rated capacity.

Why True RMS Matters for B2B Buyers

When businesses purchase digital ammeters in bulk for panel building, energy monitoring, or OEM integration, performance consistency becomes vital. Choosing the wrong measurement technology can result in a cascade of problems.

1. Incorrect Load Analysis

If you design systems based on underreported current readings, your sizing for cables, fuses, and protection devices will be incorrect. This can cause costly failures down the line.

2. Inaccurate Billing and Energy Tracking

For operations that allocate power costs internally or bill customers for energy usage, measurement accuracy is critical. Under-reading can lead to revenue loss, while over-reading causes customer disputes.

3. Reputation and Compliance Risks

For manufacturers, supplying panels or systems with inaccurate meters can damage your brand reputation and expose you to warranty claims. Meeting international accuracy standards is crucial for credibility and compliance.

Evaluating Digital Ammeters for Industrial Use

When choosing between True RMS and average sensing meters, commercial buyers should look beyond price and consider these technical aspects:

Waveform Type: Determine whether the application uses linear or nonlinear loads. If you are unsure, it is safer to choose True RMS.

Accuracy Class: Look for specifications such as 0.5%, 1%, or 2% accuracy, depending on your measurement requirements.

Input Range and Frequency Response: Ensure that the ammeter’s range and bandwidth match your expected operating conditions.

Integration Capabilities. For modern facilities, consider ammeters with digital communication interfaces like RS485, Modbus, or Ethernet. These enhance monitoring and data collection.

Display and Resolution: A clear, high-resolution digital display reduces human error and simplifies daily inspection.

Durability and Protection Industrial environments often involve vibration, temperature variation, and electrical noise. Select meters built with protective housings and robust circuitry.

The Cost vs Accuracy Tradeoff

It is true that True RMS meters generally cost more than average sensing ones. However, when viewed over the product lifecycle, the additional cost is often negligible compared to the potential losses caused by inaccurate readings.

For example:

Incorrectly sized circuit protection can lead to downtime worth thousands of dollars per hour.

Poor energy tracking can distort financial reporting or affect incentive eligibility for energy efficiency programs.

Equipment overheating caused by misread currents can shorten component life cycles and inflate maintenance budgets.

When considered from a long-term investment perspective, True RMS measurement usually delivers the lowest total cost of ownership.

Choosing the Right Supplier

Selecting a reliable digital ammeter manufacturer is just as critical as choosing the right technology. The best suppliers ensure consistent accuracy, strict quality control, and compliance with global standards. Partnering with experienced manufacturers like digital ammeter manufacturer provides access to products designed specifically for industrial demands, with rigorous testing and strong after-sales support.

A strong supplier relationship also means access to technical advice, custom specifications, and scalable production capabilities—key advantages for panel builders, distributors, and OEMs.

Looking Ahead: The Future of Measurement

Digital ammeter technology continues to evolve alongside the growing complexity of electrical systems. Smart sensors, IoT integration, and real-time diagnostics are transforming how industrial users manage and monitor energy.

True RMS sensing remains foundational to this progress. As power systems incorporate renewable energy, variable loads, and digital control, precise current measurement is the cornerstone of safety and efficiency.

Final Thoughts

In industrial settings, accuracy is not optional; it is essential. The difference between True RMS and average sensing digital ammeters can determine whether your system operates safely and efficiently or suffers from inaccurate readings and equipment stress.

For clean, simple systems, average sensing may suffice. But for the majority of modern industrial operations with harmonics, variable drives, and complex electronics, True RMS measurement is the only dependable choice.

When making bulk procurement decisions, prioritize accuracy, reliability, and long-term value over short-term cost savings. By doing so, you protect both your equipment and your reputation while ensuring smooth, efficient operations for years to come.

Comments